sales@apmwiremeshmachine.com+86-311-66792193/66792197

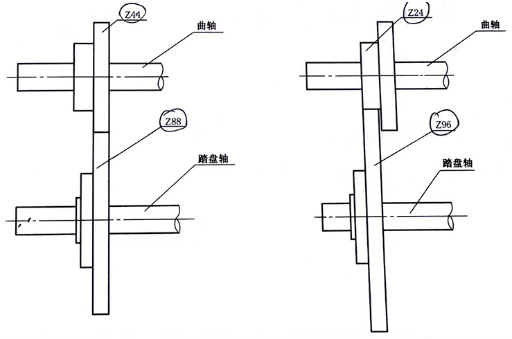

1. When weaving plain wire mesh, the main movement gear

adopts a 44-tooth wheel meshing with an 88-tooth wheel (the

44-tooth wheel at the left end of the crankshaft meshes with

the 88-tooth wheel at the left end of the pedal heald shaft).

The gear ratio is 2:1.

2. When weaving twill mesh, the main motion gear adopts 24

teeth wheel to mesh with 96 teeth wheel (Shijiazhuang loom

ZWJ-1300, Japan imported loom NAC2-1300, Zhangjiakou

loom ZWN-130), and the main motion gear adopts 29 teeth

wheel to mesh with 108 teeth wheel. The gear ratio is 4:1.

see Figure 3-18.

Figure 3-18